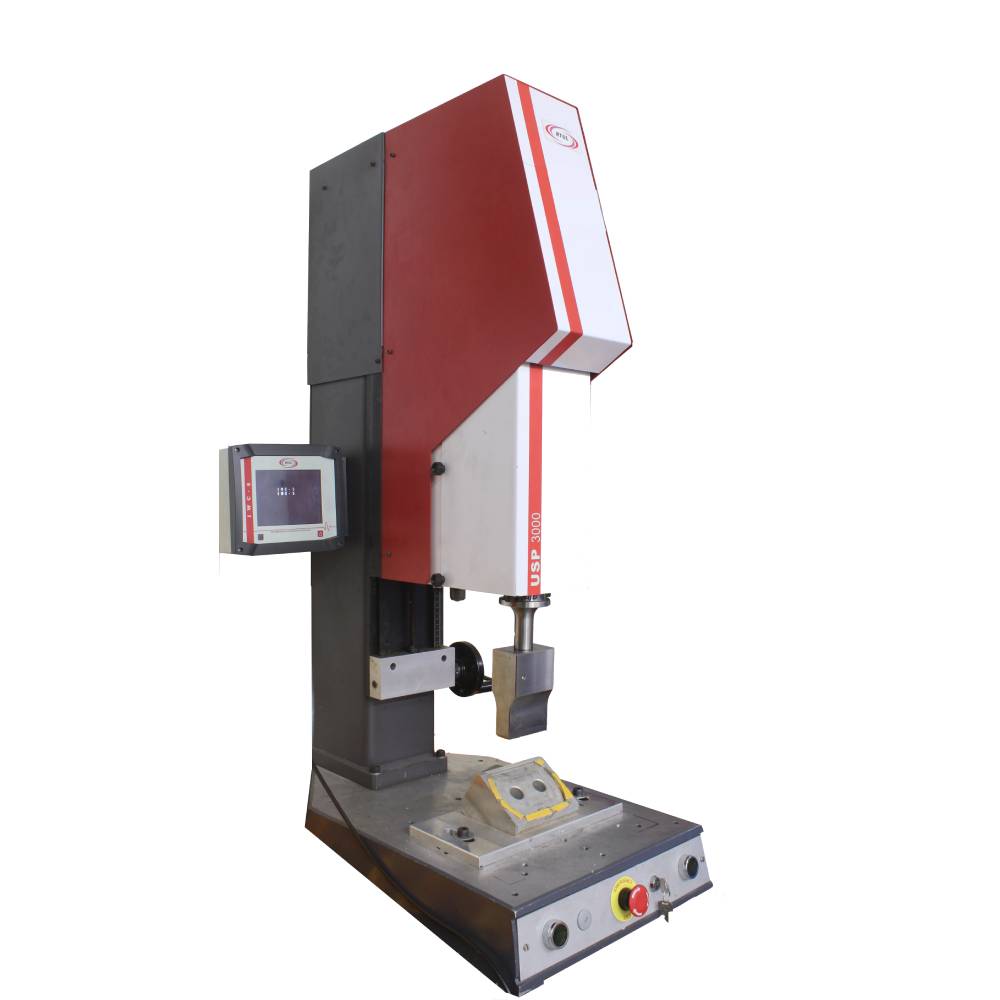

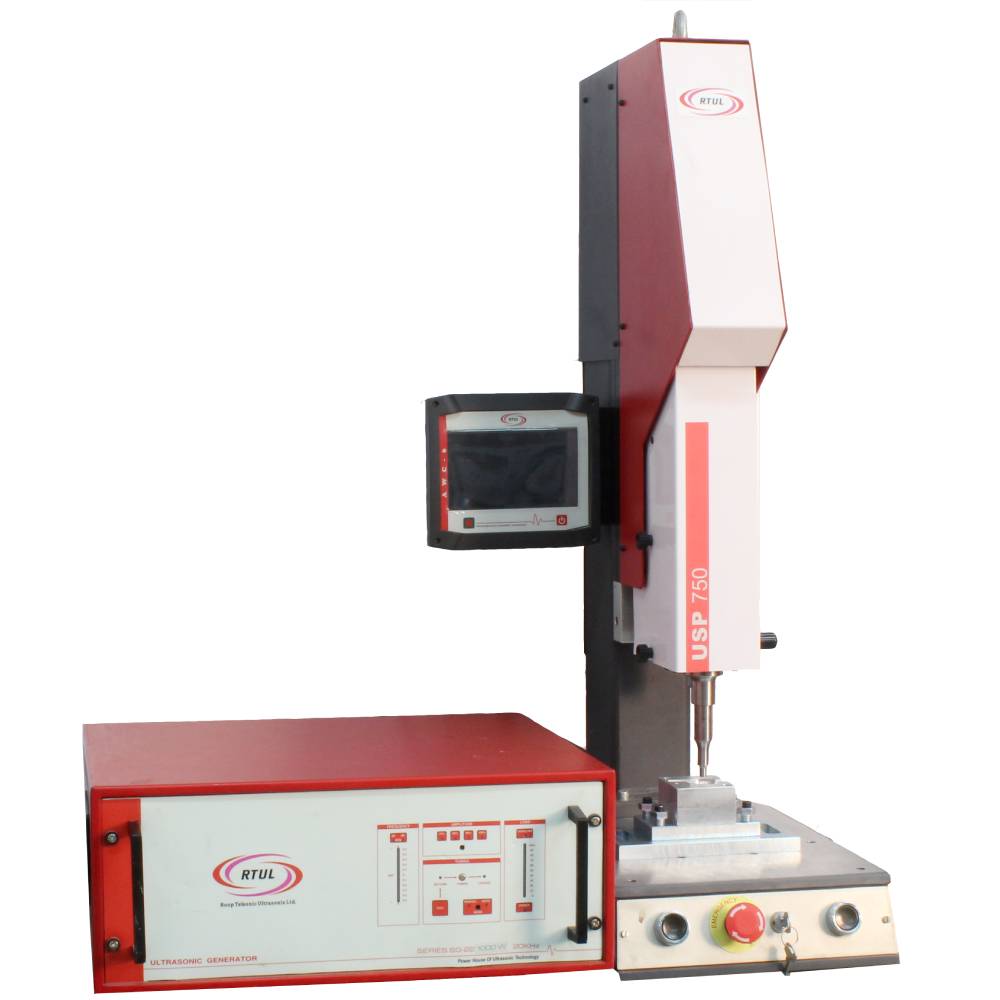

Linear Ultrasonic Plastic Welding Systems

REDEFINING THE LIMITS OF WELDING

As a joining process for industrial thermoplastics, the ultrasonic method is very well proven in practice. Particularly in the production of mass- produced parts, the process offers definite advantage over previous methods such as for instance high strength, clean weld seams, fast processing time, extremely low rejection rates and low energy consumption. In addition,this technique can be used successfully for riveting, forming, stacking as well as embedding of metal parts into thermoplastic materials.

Each ultrasonic welding installation comprises the following main components:

- Electronic ultrasonic Generator

- Transducer,booster and sonotrode

- Pneumatic Press and Control Unit

The Generator is the heart of every ultrasonic welding system, its function being to supply the transducer with an alternating current of a given ultrasonic frequency. This is then converted by the transducer into mechanical / ultrasonic vibrations which are finally transmitted via, the booster and sonotrode to the item being welded.